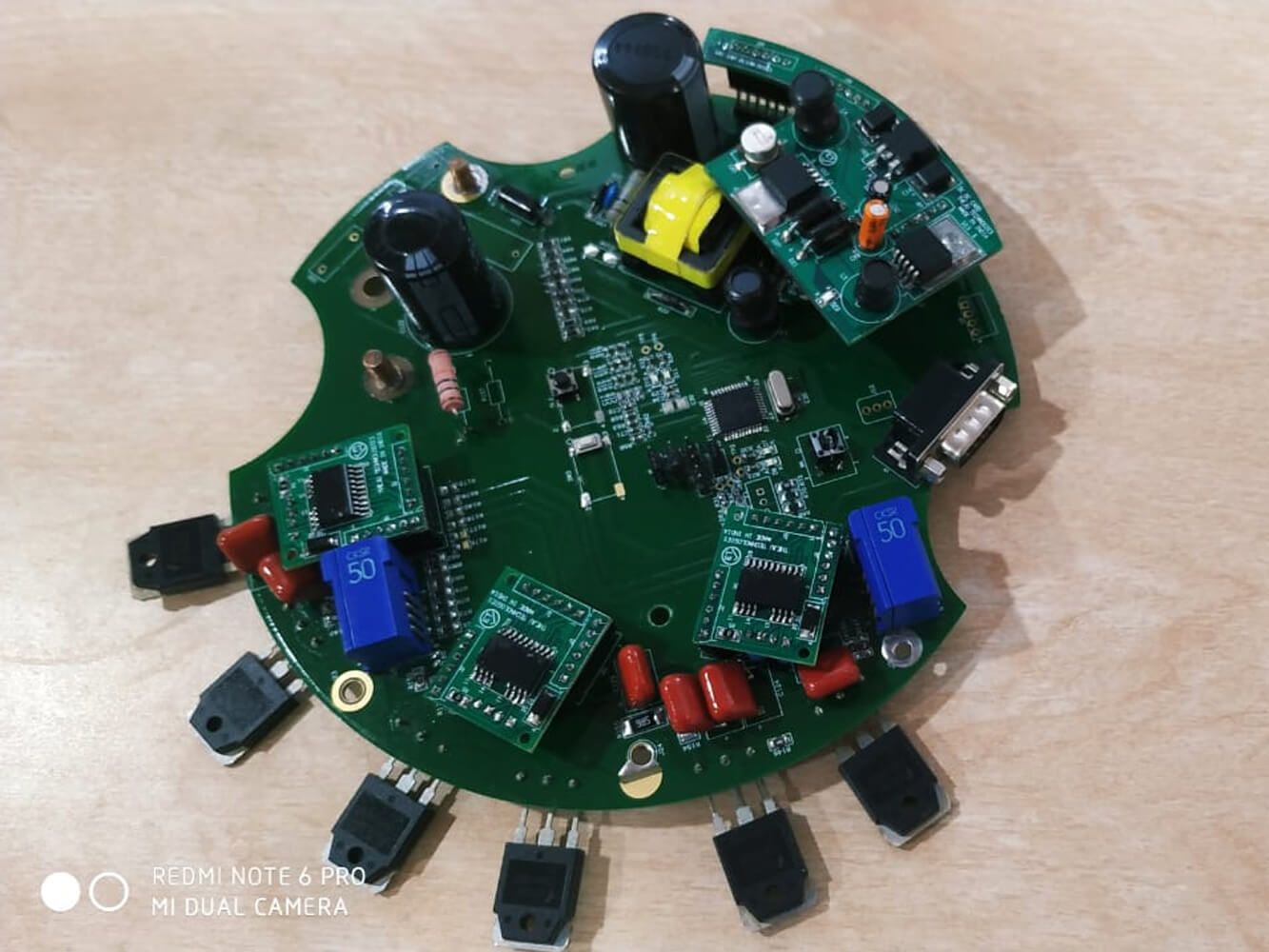

Thejutech has been developing specialized servo drives for customer need. We have a lot of experience in building high-performance specialized servo drives which are manufactured in small quantities and which can be modified in a short time to match the customer’s requirements. In this way, customer-specific servo drive projects can be supported very quickly and efficiently.

Without electronics and firmware modern motion control just would not exist. Behind any servo or stepper motor we use there is an amplifier and positioning controller. We differentiate between central and decentral (intelligence at each axis, connected with a communications bus system) topology.

InnovTouch Technologies

InnovTouch Technologies